I've been doing a hell of a lot of research on the yugang reactor and co2 reactors in general. I am looking to build my own as I have a fluval fx4 so there is no options for reactor or inline diffusion available in the UK

Is there anyone that could talk me through exact steps on setting it up? Research suggests I will need a bypass for the fx4. I have a fluval roma 240 tank and I already have co2 running by in tankdiffuser.

The main questions I have;

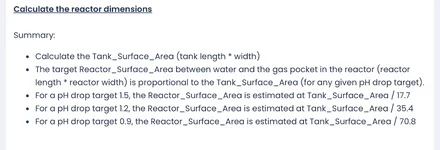

- I'd like a mid range level of co2, which seems to be a 1.2 ph drop. I've been told if I am using a standard 50mm pipe that the reactor will only need to be 27cm, which seems small, is that correct?

- If I need a bypass, does anyone have a parts list or are able to advise?

- the co2 connection that goes into the PVC, how do I get a connector into a circular PVC pipe without leaks?

Thank you so much in advance

Is there anyone that could talk me through exact steps on setting it up? Research suggests I will need a bypass for the fx4. I have a fluval roma 240 tank and I already have co2 running by in tankdiffuser.

The main questions I have;

- I'd like a mid range level of co2, which seems to be a 1.2 ph drop. I've been told if I am using a standard 50mm pipe that the reactor will only need to be 27cm, which seems small, is that correct?

- If I need a bypass, does anyone have a parts list or are able to advise?

- the co2 connection that goes into the PVC, how do I get a connector into a circular PVC pipe without leaks?

Thank you so much in advance