- Thread starter

- #201

One of our friends is going to set up a reactor in overflow mode for his 125 gallon tank. I am really looking forward to his experiences, and get confirmation if this overflow method is as easy and useful as I personally believe it is. Having other users jumping in will also help to further clarify if my tests/posts have been clear and complete enough, or that I need to do some more work.

It can be a bit challenging to find all information while reading through this rather long thread, so it I hope it helps when copy one post from our PM conversation that may be useful for others as well.

----------------------------------------------------------

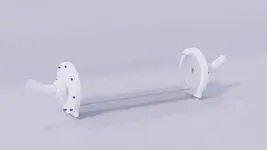

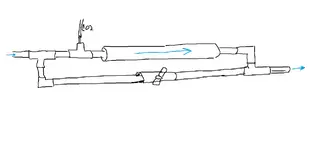

Proposed design:

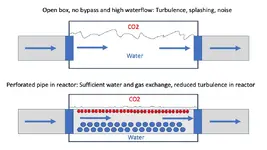

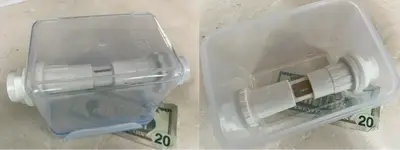

In this picture it is better to reverse the flow direction from right towards left (and inject CO2 before the reactor). Bubbles that purge from the reactor can then easily be picked up by the flow from the bypass, and do not need to travel down first. This is especially so because in overflow I like using the reactor with just a little flow so that I have no waves and only tiny bubbles escape when overflowing. When I hear from time to time (one or two times per minute) a quiet trickling noise (not gurgling by bigger bubbles) I know that my reactor works well.

When setting up for overflow mode, as said I prefer a slow flow in the reactor, that means that the bypass valve is nearly completely open. If you have a transparent reactor tube (which I recommend for various reasons) you will see a slight movement of the water, but no significant waves. I then purge air first, and then let the reactor fill itself with pure CO2 until it starts to purge. I then dial back until nearly no CO2 purges anymore, and I only from time to time hear some trickling, and see a few tiny bubbles escape into the tank. CO2 losses are then minimal, and we know that the reactor will be stable and purge itself from then onwards. As I described in a post, it is also interesting to observe through a transparent reactor tube how much gas remains after CO2 has been turned off at night. This is an indicator how well the reactor has been set up, and I am happy to explain that further if you like.

It can be a bit challenging to find all information while reading through this rather long thread, so it I hope it helps when copy one post from our PM conversation that may be useful for others as well.

----------------------------------------------------------

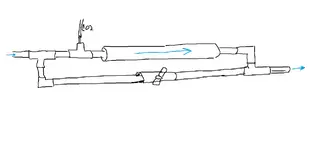

Proposed design:

In this picture it is better to reverse the flow direction from right towards left (and inject CO2 before the reactor). Bubbles that purge from the reactor can then easily be picked up by the flow from the bypass, and do not need to travel down first. This is especially so because in overflow I like using the reactor with just a little flow so that I have no waves and only tiny bubbles escape when overflowing. When I hear from time to time (one or two times per minute) a quiet trickling noise (not gurgling by bigger bubbles) I know that my reactor works well.

When setting up for overflow mode, as said I prefer a slow flow in the reactor, that means that the bypass valve is nearly completely open. If you have a transparent reactor tube (which I recommend for various reasons) you will see a slight movement of the water, but no significant waves. I then purge air first, and then let the reactor fill itself with pure CO2 until it starts to purge. I then dial back until nearly no CO2 purges anymore, and I only from time to time hear some trickling, and see a few tiny bubbles escape into the tank. CO2 losses are then minimal, and we know that the reactor will be stable and purge itself from then onwards. As I described in a post, it is also interesting to observe through a transparent reactor tube how much gas remains after CO2 has been turned off at night. This is an indicator how well the reactor has been set up, and I am happy to explain that further if you like.

Last edited: